Collection: Knitting patterns

10+ years of designs

I've had the good luck and privilege to be part of a flourishing knitting renaissance. In 2010, I added my first design to Ravelry and since then I've written two books and many, many more knitting patterns. Here are some of my favourites. For a full list of my patterns, please check out my page on Ravelry. Happy knitting!

-

Arbois Cardigan

Regular price $7.00 USDRegular priceUnit price / per -

Arimono Shawl

Regular price $7.00 USDRegular priceUnit price / per -

Boiseau Wrap

Regular price $7.00 USDRegular priceUnit price / per -

Clairette Cardigan

Regular price $7.00 USDRegular priceUnit price / per -

Claro Wrap

Regular price $6.50 USDRegular priceUnit price / per -

Cordova Cardigan

Regular price $6.50 USDRegular priceUnit price / per -

Cultivar Cardigan

Regular price $7.00 USDRegular priceUnit price / per -

Fifth Street Jacket

Regular price $6.50 USDRegular priceUnit price / per -

Fledge Shawl

Regular price $6.50 USDRegular priceUnit price / per -

Galiano Vest

Regular price $6.50 USDRegular priceUnit price / per -

Gatineau Hat

Regular price $6.50 USDRegular priceUnit price / per -

Helliwell Cardigan

Regular price $7.00 USDRegular priceUnit price / per -

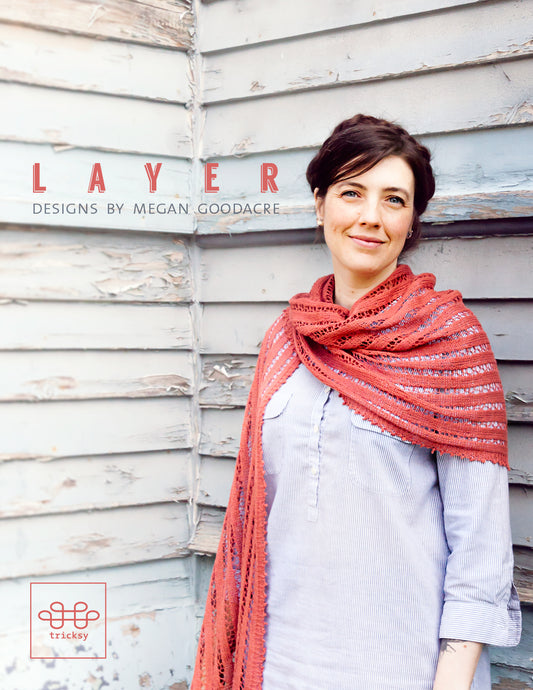

Layer Collection - 5 Patterns

Regular price $19.99 USDRegular priceUnit price / per -

Lundell Pullover

Regular price $7.00 USDRegular priceUnit price / per